If I was any good at running a company I would have been writing progress updates through out the project, however quite simply, I didn’t. So a quick overview will have to do… To say I was in my element was an understatement. They don’t call me Sticky Daisy for nothing, always got my fingers in a jar of jam or a pot of PVA. Very quickly the light switches in my studio went from being covered in peanut butter and ketchup to motorbike oil and grease.

Suzuki pretty much sent me an Ikea-make-it-yourself-motorbike, every part and panel under the sun. Packages three times the size of me were delivered, with endless materials from spark plugs to double-bubble visor screens. I LOVED IT. Fairly sure I can only refer to my friends as ‘acquaintances’ now after bombarding them with endless Snapchats of various bits of bike. Something I soon realised, unsurprisingly, no one gives a toss about.

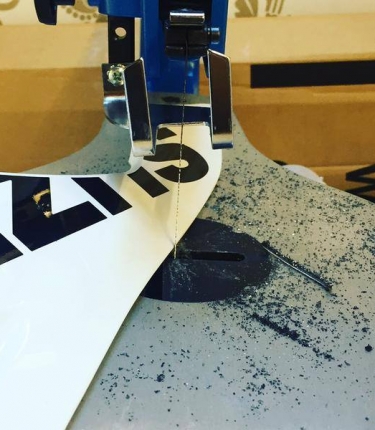

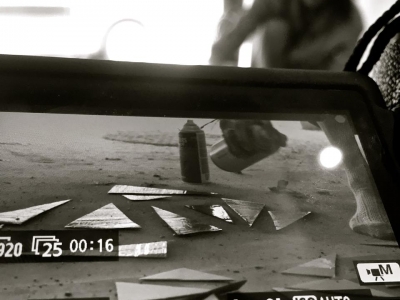

What I’m yet to mention is that Suzuki also commissioned three short films - Each one documenting the making process of each of the dresses. The only downer being that every swear, every injury, every major fuck-up (where I accidentally cut the wrong bit off a £700 side-panel or put a pillar box drill through my thumb) is now caught on film. The videographer has been kind enough to put together a short ‘C-reel’, which is just a steady stream of me dropping the C-Bomb in varying aggressive tones across the six month period.

After a lot of hard graft, a huge lack of sleep and two severe emotional meltdowns, the dresses were completed. And I wont lie, I was a right old Chuffty Pants. I make dresses out of rubbish, yes, however this time I stepped it up a gear (wreyyy bike pun). This project involved an incredible amount of skill, accuracy and even just basic physics… for example, factoring in the common law of gravity is something that had never shown itself to be an issue before. But they were done. And HOT DAMN, they look like a sexy bitta kit.